In manufacturing, we often focus on precision, strength, and functionality. But there’s one crucial step that quietly makes all the difference—the finish. Whether it’s smoothing sharp edges, polishing surfaces, or preparing parts for coating, industrial finishing tools play a behind-the-scenes role in getting parts production-ready.

A guide to industrial finishing tools, their applications, and how to choose the right tools for your operation.

What Are Industrial Finishing Tools

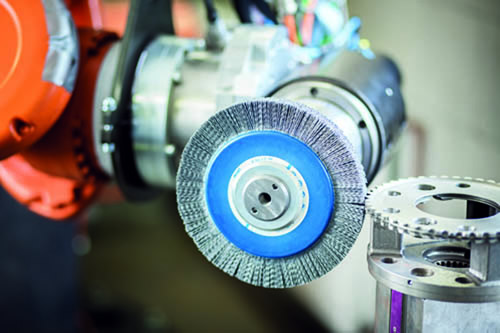

Industrial finishing tools designed to give manufactured parts their final touch. This could mean anything from grinding and sanding to polishing or deburring. They help improve performance, extend product life, and make things look a lot better, too.

Types of Industrial Finishing Tools

-

Grinding Tools

-

Used for removing excess material and preparing surfaces.

-

Common in metal fabrication and machining.

-

Types: Angle grinders, belt grinders, surface grinders.

-

-

Deburring Tools

-

Essential for removing sharp edges and burrs after cutting or drilling.

-

Include manual deburring tools, rotary tools, and brush systems.

-

-

Polishing & Buffing Equipment

-

Used for creating smooth, reflective surfaces.

-

Includes polishing wheels, buffing pads, and compounds.

-

-

Sanding Tools

-

Employed for wood, metal, plastic, and composites.

-

Options include orbital sanders, belt sanders, and sanding sponges.

-

-

Shot Blasting & Media Blasting

-

Ideal for cleaning and texturing surfaces.

-

Media options include glass beads, aluminum oxide, and steel shot.

-

Where Are These Industrial Finishing Tools Used?

Finishing tools show up just about everywhere in manufacturing. A few examples:

-

Aerospace – Removing burrs and polishing parts that can’t afford to fail.

-

Automotive – Prepping surfaces for paint and improving aesthetics.

-

Electronics – Smoothing out enclosures or circuit boards.

-

Heavy machinery – Prepping surfaces for coatings or welds.

Finishing might be the last step in production, but it’s one of the most important. With the right Industrial Finishing tools and techniques, you’ll not only make your parts look great—you’ll also improve their function, safety, and lifespan.