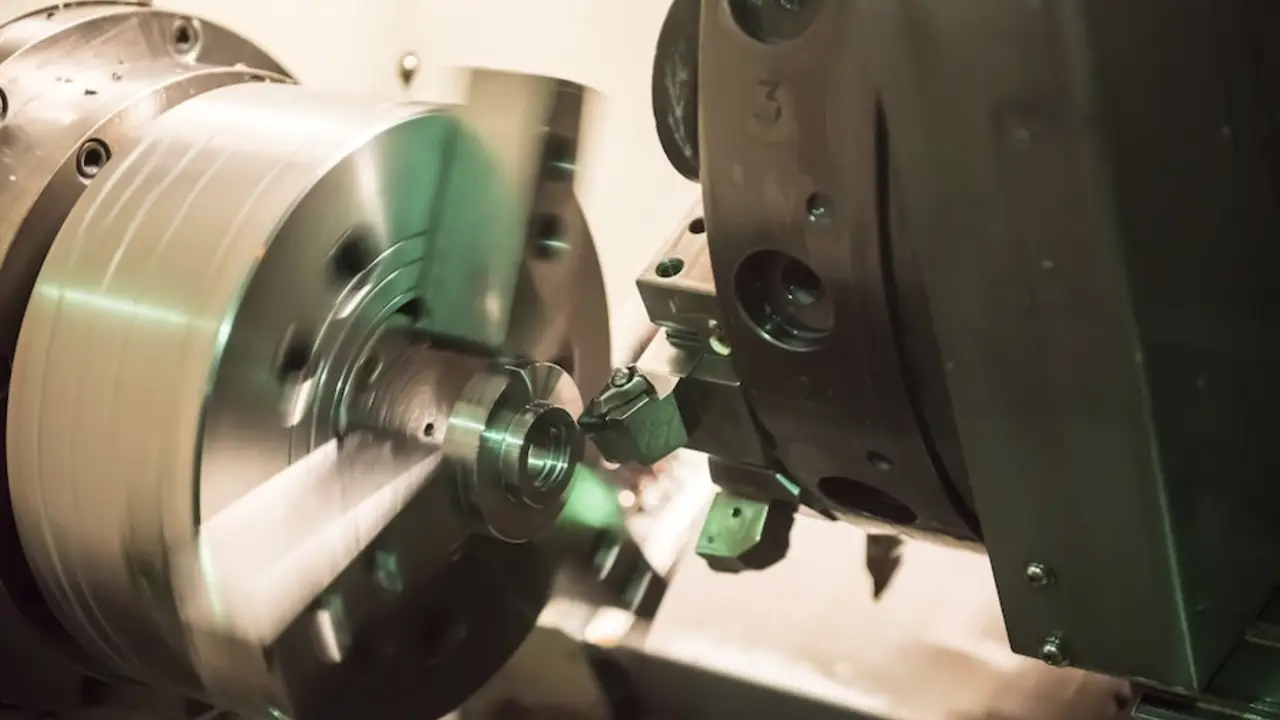

When things are made in factories, they often have rough edges or bits of extra material called ‘burrs.’ Automated deburring solutions are a way to get rid of those rough spots using machines. It makes the manufacturing process much faster and better. Think of it like this: instead of someone carefully sanding down each part by hand, a machine does it quickly and exactly the same way every time. This helps make sure all the parts are smooth and safe.

Manual Vs. Automated Deburring

I think now you have understood what deburring is. So, there are two main ways to get rid of those rough edges, or ‘burrs’. One is manual deburring tools (doing it by hand) and another one is automated deburring machines (using machines).

Doing it by Hand (Manual Deburring)

- This is the old-fashioned way. Many people use deburring tools like files or sandpaper to smooth the edges but iIt takes a lot of time and hard work.

- Because people do it, mistakes can happen, and each part might end up a little differently.

- It can also be dangerous if someone gets hurt by the sharp edges.

Using Machines (Automated Deburring)

- This is the newer, faster way. Industrial deburring tools or robots do the work.

- It is much quicker and more efficient.

- The machines do the same thing every time, so all the parts are exactly the same.

- It is safer because machines are doing the work instead of people.

How Automated Deburring Improves Manufacturing Efficiency?

Remember, automated deburring solutions mean using machines to get rid of rough edges. Here are how that helps.

-

Improved Production Efficiency and Consistency

Machines are way faster than people doing it by hand. This means factories can make more things in less time. Machines do the same thing every time, so every part is smooth and exactly the same.

-

Increased Accuracy and Precision

Advanced deburring technology uses special tools like sensors and vision systems to find and remove rough edges very precisely. This makes sure every part is perfect.

-

Reduced Labor Costs and Workplace Injuries

Factories don’t need as many people to do the hard work of deburring tools for manufacturing industry. This saves money. It is also safer because people don’t have to handle sharp edges as much.

-

Improved Surface Quality and Finish

Deburring solutions don’t just remove the rough edges; they also make the parts smoother overall. This makes them better for putting other things together.

-

Longer Tool Life and Reduced Wear and Tear

Deburring supplier solutions can be designed to handle parts gently, reducing the wear on tools and machinery compared to manual handling.

Conclusion

Basically, using machines to smooth out rough edges (automated deburring machines) is a big win for factories. By using machines, manufacturers achieve faster, more consistent, and safer production. This method ensures precise, high-quality parts while reducing costs and improving overall output.

For top-tier deburring solutions and finishing solutions that deliver quality and performance across diverse industries, partner with IMEXSU, a trusted leader with decades of experience.